5 Axis Machining Service Supplier

As a leading 5-axis CNC machining factory in China, KLARM is dedicated to delivering precision machined parts for a wide range of industries. With state-of-the-art equipment, highly advanced technology, and a skilled team of professionals, we specialize in providing high-quality machining solutions tailored to meet the needs of aerospace, automotive, medical, and other sectors.

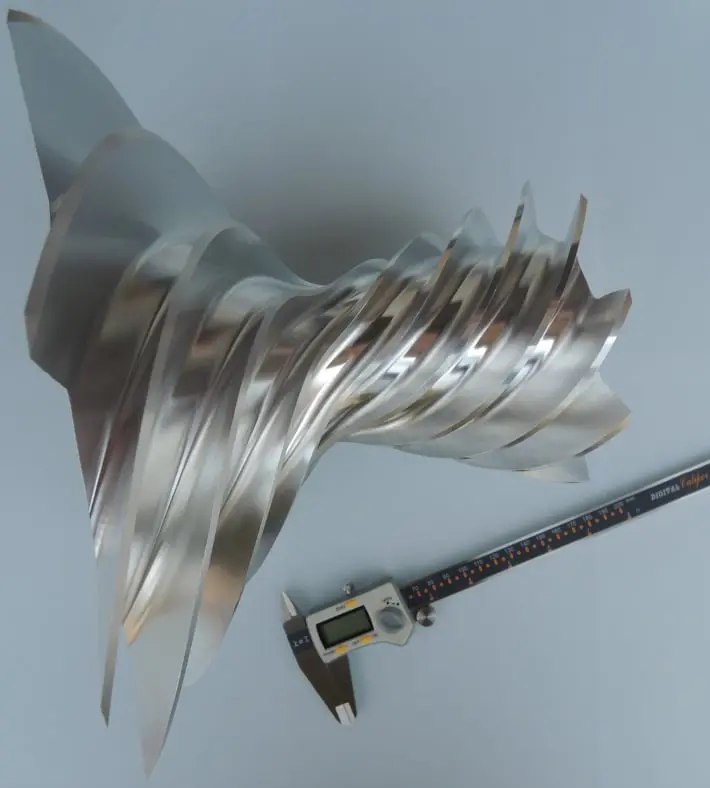

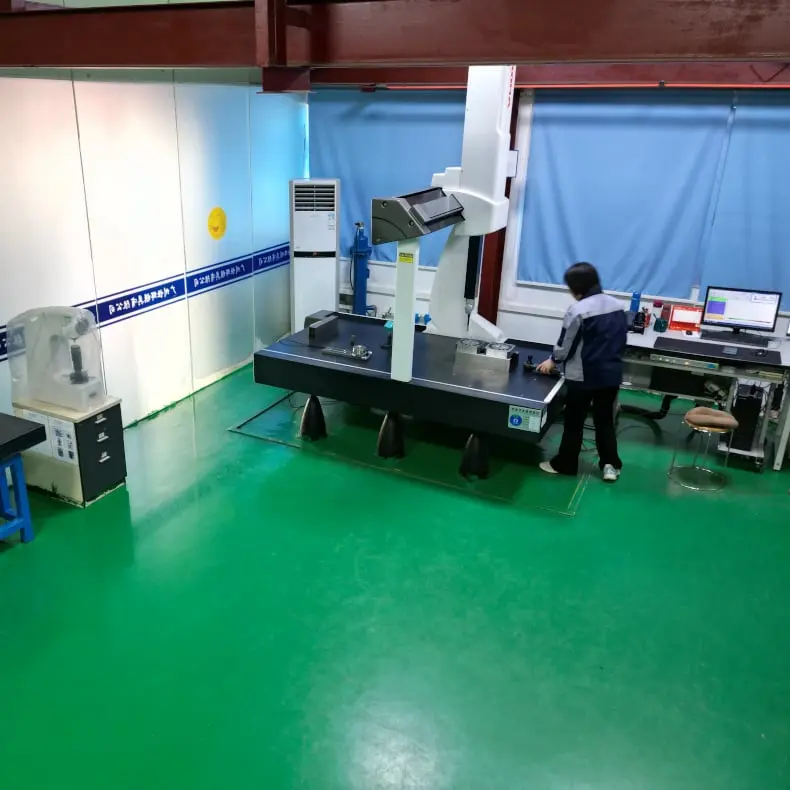

Our facility is equipped with cutting-edge 5-axis CNC machines, enabling us to produce complex geometries with unparalleled accuracy and efficiency. From prototyping to mass production, we are committed to achieving excellence in every project. Our streamlined processes, combined with rigorous quality control standards, ensure that every part exceeds clients' expectations.

We pride ourselves on our customer-centric approach, offering competitive pricing, rapid turnaround times, and comprehensive support throughout the manufacturing process. Whether you're seeking custom parts or high-volume production, our factory is your trusted partner for precision machining in China.