Check out these 7 axis machining images:

Saturday Mini Shopping Roadtrip

Image by F.d.W.

Saturday Mini Shopping Roadtrip

A windmill is a mill that converts the energy of wind into rotational energy by means of vanes called sails or blades.[1][2] Centuries ago, windmills usually were used to mill grain, pump water, or both. Thus they often were gristmills, windpumps, or both.[3] The majority of modern windmills take the form of wind turbines used to generate electricity, or windpumps used to pump water, either for land drainage or to extract groundwater.

Windmills in antiquity

Heron’s wind-powered organ

The windwheel of the Greek engineer Heron of Alexandria in the first century is the earliest known instance of using a wind-driven wheel to power a machine.[4][5] Another early example of a wind-driven wheel was the prayer wheel, which has been used in Tibet and China since the fourth century.[6] It has been claimed that the Babylonian emperor Hammurabi planned to use wind power for his ambitious irrigation project in the seventeenth century BCE.[7]

Horizontal windmills

The Persian horizontal windmill

Hooper’s Mill, Margate, Kent, an eighteenth-century European horizontal windmill

The first practical windmills had sails that rotated in a horizontal plane, around a vertical axis.[8] According to Ahmad Y. al-Hassan, these panemone windmills were invented in eastern Persia as recorded by the Persian geographer Estakhri in the ninth century.[9][10] The authenticity of an earlier anecdote of a windmill involving the second caliph Umar (AD 634–644) is questioned on the grounds that it appears in a tenth-century document.[11] Made of six to 12 sails covered in reed matting or cloth material, these windmills were used to grind grain or draw up water, and were quite different from the later European vertical windmills. Windmills were in widespread use across the Middle East and Central Asia, and later spread to China and India from there.[12]

A similar type of horizontal windmill with rectangular blades, used for irrigation, can also be found in thirteenth-century China (during the Jurchen Jin Dynasty in the north), introduced by the travels of Yelü Chucai to Turkestan in 1219.[13]

Horizontal windmills were built, in small numbers, in Europe during the 18th and nineteenth centuries,[8] for example Fowler’s Mill at Battersea in London, and Hooper’s Mill at Margate in Kent. These early modern examples seem not to have been directly influenced by the horizontal windmills of the Middle and Far East, but to have been independent inventions by engineers influenced by the Industrial Revolution.[14]

Vertical windmills

Due to a lack of evidence, debate occurs among historians as to whether or not Middle Eastern horizontal windmills triggered the original development of European windmills.[15][16][17][18] In northwestern Europe, the horizontal-axis or vertical windmill (so called due to the plane of the movement of its sails) is believed to date from the last quarter of the twelfth century in the triangle of northern France, eastern England and Flanders.[citation needed]

The earliest certain reference to a windmill in Europe (assumed to have been of the vertical type) dates from 1185, in the former village of Weedley in Yorkshire which was located at the southern tip of the Wold overlooking the Humber estuary.[19] A number of earlier, but less certainly dated, twelfth-century European sources referring to windmills have also been found.[20] These earliest mills were used to grind cereals.[citation needed]

en.wikipedia.org/wiki/Windmill

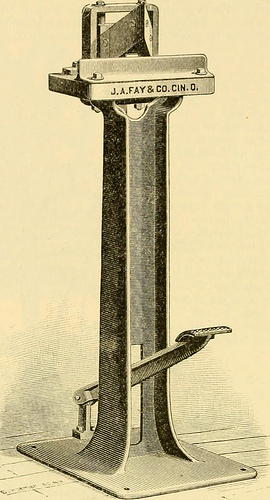

Image from page 193 of “Modern mechanism, exhibiting the latest progress in machines, motors, and the transmission of power, being a supplementary volume to Appletons’ cyclopaedia of applied mechanics” (1892)

Image by Internet Archive Book Images

Identifier: modernmechanisme00benj

Title: Modern mechanism, exhibiting the latest progress in machines, motors, and the transmission of power, being a supplementary volume to Appletons’ cyclopaedia of applied mechanics

Year: 1892 (1890s)

Authors: Benjamin, Park, 1849-1922

Subjects: Mechanical engineering

Publisher: New York, D. Appleton

Contributing Library: Mugar Memorial Library, Boston University

Digitizing Sponsor: Boston University

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

re different sizes, the one most in use being 100 ft. long by 30 ft. broad, andhaving a draft of 7 ft. of water. The hulls and entire machine are constructed of iron, insections, in France, shipped to Colon, and transhipped at different points along the line wherethey arc to l»e used. The cost is, approximately, ifl 15,000 at Colon, not including cost oferection, which has been an exfiensive work at Panama, some engineers estimating the cost oferection af 35 per cent on original value. The tower is quite low, the elevation of liopperbelow upper tumliler tieing oidy 20 ft. above water-level, {lie ladder is in one section, sup-ported upon axis in tower, and varies in length to the use of dredge in attacking new banksor in deepening channels. The buckets are of iron, wrought in one piece, the links iu-ing anintegral part. The power is derived from a vertical engine, having three pistons, which actdirectly upward on a crank-shuft, which has a gear-wheel ;it either end. and large balance-

Text Appearing After Image:

FiG. 1.—Dovetailing-machine. DREDGES AND EXCAVATORS. 179 wheels. These gear-wheels connect through two other gear-wheels to the upper turabler-shaft,thus •iviti^ a positive power, and when the machine is dredging in rock no slipping occurs,as in a beltconnection. The engines are 180 horse-power in this sized dredge, and it forms amo^t powerful machine, so tliat in attacking hard-pan or loose rock it receives such a force asto accomplish its work when buckets and links do not break. In ordinary work in sand,gravel, clay, and loose material, a positive force is not necessary, as in rock-work. The largebelt from a horizontal engine connecting with a gear attachment fitted with a tightener-pul-lev. increasing or diminishing the tension, has given good satisfaction, and controls the move-ments, except in rock-work, .u -.on*.. 1, JiUThe dimensions of a Fren(;h dredge of large type are as follows: Length, IZO ft.; breadth,28 ft • depth, 10 ft.; draft, 7 ft.; depth of working, 28 ft.: s

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.