Image from page 305 of “The flotation method” (1916)

Image by Internet Archive Book Pictures

Identifier: flotationprocess00richuoft

Title: The flotation approach

Year: 1916 (1910s)

Authors: Richard, Thomas Arthur, 1864-

Subjects: Flotation

Publisher: San Francisco Mining and Scientific Press

Contributing Library: Gerstein – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click here to view book on the web to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Just before Image:

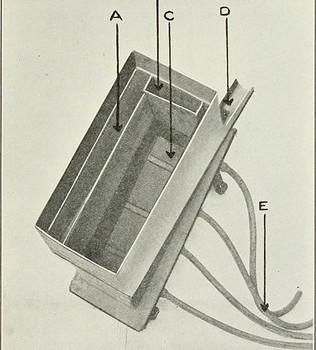

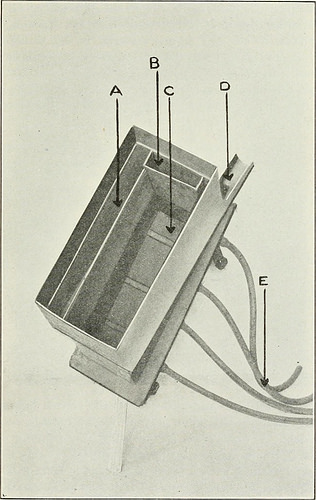

-Glass Jar. -4 Baffles. Impeller. ^ Wooden Cork.— Pipe Nipple.Verify Valve. /Air Inlet. Fig. 69. owen test-machine. A novice will have no modest difficulty in operating such aninstallation, as there are a number of items to be kept in operationat the same time. The mixture of ore, water, oil, and any otherreagents is fed either into the suction of the sand-pump or into the topof the Pachuca soon after air has been began into the numerous machines.The overflow from the Pachuca into the rougher-cell accumulates TESTING ORES FOR THE FLOTATION PROCESS—II 297 until a nice froth is coming up and nearly overflowing. Then thetailing-discharge valve on the rougher is gradually opened and frothallowed to overflow from the cell into the cleaner-cell. It is bestto get most of the charge circulating prior to significantly concentrate-froth

Text Appearing After Image:

Fig. 70. the callow cell (early form). A. Froth-overflow launders. B. Pulp-feed to air-blankets. C. Aii–atomizing blanket. D. Concentrate discharge. E. Compressed-air feed to wind-boxes. 298 THE FLOTATION Procedure is allowed to overflow, the overflow of froth becoming controlled bythe primary air-valves major to each and every unit. Following the valves intothe person wind-boxes beneath the machine have been onceadjusted they need to by no means be disturbed, and all control of airsupplied should be at the valves in the primary pipes. When every single-issue is going effectively, the air-pressure in the cleaner can be increaseduntil concentrate-froth is overflowing into the vacuum-filter. Awooden paddle to stir any settled material in the flotation cells isof value, as properly as a small jet of water from a rubber hose forwashing concentrate along the froth-launders and for beating downfroth when occasional too-violent rushes of froth from the cells takeplace. Right after a test is total the pulp must be drained completelyfro

Note About Photos

Please note that these images are extracted from scanned page images that might have been digitally enhanced for readability – coloration and look of these illustrations might not completely resemble the original work.

Hermle open property in Germany gets enthusiastic response

The newest machine model, the C 52 U MT dynamic features 5-axis simultaneous milling as nicely as profile turning capabilities. A demonstration machining a shrouded impeller highlighted its positive aspects in each technologies. The exhibit also highlighted …

Read far more on Aerospace Manufacturing and Style

Bredel Expands Apex Hose Pump Variety

Current international product trials across a range of applications have place the new Apex models to the test in method-critical abrasive slurry transfer operations. User feedback has demonstrated that, when compared with existing pump technologies such …

Study more on Impeller.net (press release)