Some cool turbine blades manufacturing pictures:

Image from web page 576 of “Journal of electricity, power, and gas” (1899)

Image by Web Archive Book Photos

Identifier: journalofele323271914paci

Title: Journal of electricity, energy, and gas

Year: 1899 (1890s)

Authors: Pacific Coast Electric Transmission Association

Subjects: Electrical engineering Electrical energy Gas manufacture and performs

Publisher: San Francisco : Technical Pub. Co.

Contributing Library: San Francisco Public Library

Digitizing Sponsor: California State Library Califa/LSTA Grant

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click here to view book on-line to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Before Image:

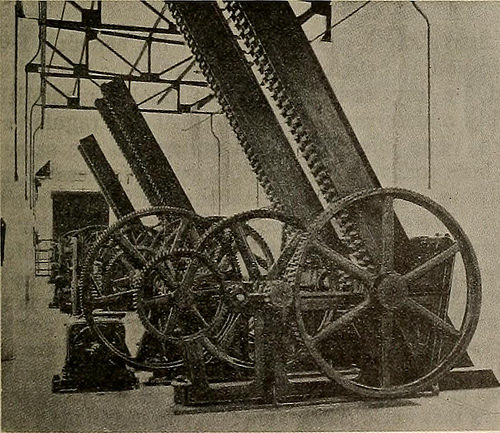

he de-flecting nozzle is used only on the impulse variety ofwater wheel, and so arranged that the water is de-flected from the runner blades. Draft Tubes and Tail Races. When the water leaves the turbine runners andproceeds through the draft chest into the draft tube,it ordinarily has a considerable velocity head whichshould be progressively converted into stress head byso shaping the draft passages that the velocity is uni-formly decreased to a minimum. It is readily appre-ciated that the above would only be achieved byeliminating any sudden adjustments in the path ofthe water. The plant ought to be so positioned with respect to thetail race that full advantage is taken of what ever drafteffect there may possibly be accessible. In general, tail raceshould consist of as unrestricted a water passage asconditions will permit. Electrical Manage. In designing a hydroelectric plant, care need to begiven to the topic of electrical manage. If achievable,the switchboard ought to be, for the sake of hassle-free

Text Appearing Soon after Image:

Electrically Operated Heaclgates. operation, compactly arranged. In most situations theswitchboard is positioned in full view of the plant andreadily accessible to the various parts of it. All re-mote controlled motors and solenoids on auxiliary ap-paratus must preferably be achievable of operation froma point adjacent to the switchboard. A plant so de-signed will be much more economical to operate than a plantin which the control devices are installed at variouspoints, since the operator can accomplish more atthe time when his solutions are most required. Electrically operated headgates are utilised exten-sively, resulting in a saving of labor and acting as aprotection to the plant in case of trouble. All modernplants are equipped with remote controlled governors,so that the speed might be varied by the switchboardoperator for purposes of synchronizing and as a meansof load adjustment when the machine is operating onthe method. Remote electrical handle in case of fieldrheostats enables the rheostat t

Note About Images

Please note that these images are extracted from scanned web page pictures that may possibly have been digitally enhanced for readability – coloration and look of these illustrations may possibly not completely resemble the original perform.