Appendix D doesnot have values for minor axis bending allowable stresses

Combining this with the major axis tensile bending stress of 1.15 ksi producesa maximum bending tensile anxiety of 1.28 ksi. This is still much less than the axialcompressive anxiety of 4.1 ksi, so the entire cross section is in a state of(nonuniform) compression.

For minor axis bending compression, we note that a beam bent about itsweak axis is not subject to lateral buckling. Additionally, the net lies on theneutral axis, so it want not be checked for neighborhood buckling. Appendix D doesnot have values for minor axis bending allowable stresses, so we will haveto calculate the allowable neighborhood buckling tension for the anges. We can turnto Appendix D to nd that the b/ t ratio of the anges is five.96. From Figure5.56, we see that this is less than S

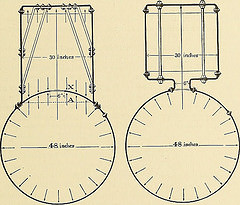

, and the allowable minor axis localMember No. 34—Shear Lastly, let’s address shear stress.The allowableshear anxiety in the internet is a function of its h/t ratio, which for shear in atplate webs is primarily based on the clear height in between the anges. From the dimensionsprovided in Appendix B, we can calculate h/ t as follows:

Note that this is slightly greater than the b/ t ratio of 29.13 given in AppendixD for the net in compression, exactly where the llets had been deducted from the heightof the net. We see from Table 7.15 that 31.74 is much less than SBecause the member has each axial force and bending, we need to verify itfor combined stresses. From Section 7.four, we see that there are two situations tocheck for combined compression and bending, and one more case to verify forcombined shear, compression, and bending. We’ll commence with Equation 7.9.

The only new variable in this equation is F, which is the allowablecompressive pressure of the member regarded as a quick column. A shortcolumn would have an all round slenderness ratio much less than Sao, for which theallowable overall column buckling tension is offered in Table 7.four as 19 ksi. Theallowable compressive stress will, therefore, be restricted by the allowable bucklingstress forelements of the column, which is offered in Table 10.8 as 17.six ksi.We can now express this combined stress equation as.

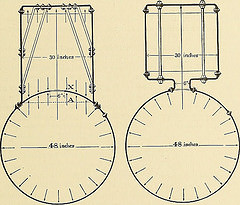

Member No. 84—Axial Compression Considering that we are using the exact same trial membersize as for member no. 34, the only parameter that will adjust in determiningthe general column slenderness ratio is the member length (L). Theoverall column slenderness ratio, is then:When once again, we must establish the unbraced length of the compression

ange (L) to calculate the lateral buckling allowable tension. The momentdiagram for member no. 84 (see Figure 10.22) shows that the leading ange isin compression for the whole length of the member. Due to the fact this is the angebraced by the panels, the unbraced length (Lb) is equal to . From Table 7.9we see that the allowable stress for lateral buckling is then 21 ksi. We comparethis to the allowable pressure for elements of beams from Appendix D.

My name is Amanda Li , this website consists of a great high good quality merchandise such as China Immo Reader, FORD VCM IDS Manufacturer, welcome to visite Auto Diagnostics Tools .